CNC-controlled, hydraulic press brake GBP PRO S

Four driven axes, DELEM DA 58T touchscreen control, motorised crowning and manual upper tool quick clamping

Product Details

The GBP PRO S series is already suitable for more demanding tasks. In the standard version, the machine is equipped with four controlled axes (Y1, Y2, X and R) and motorised table crowning. With the Delem DA-58T 2D controller including a license for the Profile TL offline software, your products can be programmed directly on the machine or at your desk. A very wide range of options is available for the PRO S-Line. Additional backgauge extensions with up to 6 axes, hydraulic tool clamps, motorised bending aids and much more are available here. Working widths from 1250mm to 6100mm and pressing capacities from 60t to 400t can be supplied as standard for this series - we will be pleased to configure special sizes on request.

- Graphical 2D CNC control Delem DA-58T with offline software TL for convenient programming via touch interface

- High quality linear encoder from the Italian manufacturer GIVI Misure with a resolution of 0.01mm for exact positioning of the press bar and thus high precision when bending

- X-axis with Mitsubishi servo drive, recirculating ball screw and double linear guide on each side for stable guidance and optimum absorption of the tilting moment and lever forces, ensuring very good positioning even at high speeds

- R-axis with Mitsubishi servo drive, ball screw and double linear guide per side for precise positioning and long service life of the ball screw

- Two backgauge fingers on solid beam with double linear guide for maximum stability in Z-direction

- Motorised table crowning original Wila with Framo motor from Germany for a homogeneous bending angle

- Safety lasers and PLCs from the market leader Fiessler from Aichwald for maximum safe working with the greatest possible flexibility

- Massive quadruple guide of the upper beam for an optimally supported movement and a vertical dissipation of the pressing forces

- Manual upper tool clamping type Promecam/Amada for tool-free, lateral tool changing

- Complete upper tool set made in Italy including deer foot stamp for box bending

- Complete lower tool set with quadruple opening made in Italy for bending material thicknesses from 1mm to 8mm

- Mobile foot control unit from Bernstein in North Rhine-Westphalia for controlling the upper beam

- Two front sheet support brackets on linear guides that can be moved in the longitudinal axis to the respective tool station for easier material handling

- High-quality hydraulics from Hoerbiger in Schongau

- Electronic components from Schneider and Mitsubishi

- Side door monitored by switch and monitored rear area by Reer light curtain from Italy

- Bright and energy-saving work area and rear area lighting by means of LED strips

- Complete oil filling with branded hydraulic oil from Eni

- Delem DA-66T 2D CNC graphic control with TL offline software for intuitive, graphic input of profiles via the very generous 17" touchscreen display

- Delem DA-69T 3D graphic CNC controller with offline software for programming products in 3D and importing DXF, IGES and STEP

- Cybelec controls

- Fiessler AKAS 3PM safety laser for automatic laser setting with the option of moving the upper beam in rapid traverse up to 2mm above the workpiece surface

- Additional foot pedal for two-man operation

- Control and switch cabinet on the left-hand side of the machine, if structural conditions or space requirements make this necessary.

- 4-axis backgauge X, R, Z1, Z2 for bending complex parts at different tool stations

- 5-axis backgauge X, R, Z1, Z2, Delta X for inserting and edging tools at an angle

- 6-axis backgauge in tower design X1, X2, R1, R2, Z1, Z2 for traversing in all three dimensions

- Hydraulic upper tool clamping WILA PRO for more comfort and less time spent with frequent tool changes

- WILA PRO hydraulic die clamping for more convenience and less time spent on very frequent die changes

- Hydraulic unit "Power Pack" in combination with hydraulic upper tool and/or lower tool clamping

- Additional backgauge finger for standard backgauge for bending complex parts at different tool stations

- Additional front support brackets without handwheel height adjustment to simplify material handling for very long and/or heavy workpieces

- Motorised bending aids for very large and very heavy workpieces that can no longer be held or guided by muscle power.

- Parking position for motorised bending aids, in order to park them outside the working area and thus enable the use of the entire machine width if necessary

- Manual central lubrication unit to carry out the lubrication of the upper beam guide centrally via an easily accessible lever

- Automatic central lubrication unit for automatic lubrication of the upper beam guides

- Oil cooler for a constant oil temperature when used in series production or in 2- or 3-shift operation

- Oil heating to protect the hydraulic components when operating in a non-heated environment with the first stroke

Bending length and press force are essential factors when it comes to choosing the right press brake. If the required press force increases, the bending length also increases proportionally. The GBP PLUS press brake is available with a bending length of 1,250 mm and a pressing force of 60 tonnes. The largest version has a bending length of 6,100 mm and a pressing force of 600 tonnes. Other sizes are available on request.

Impressions

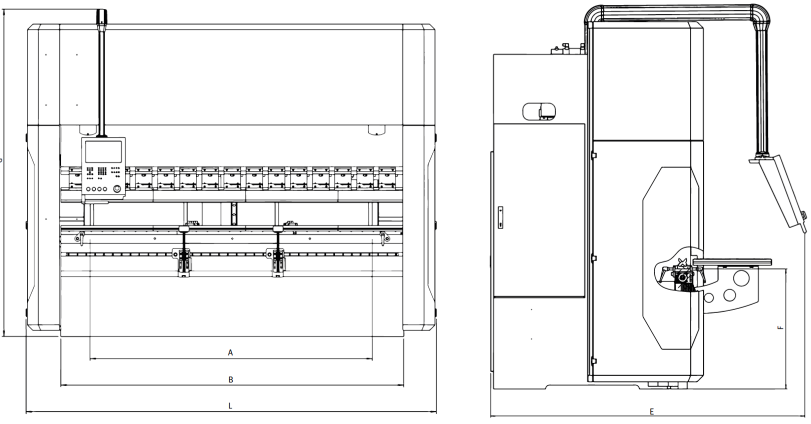

Construction

| Machine type | Working width | Pressing force | Stand passageway | Outreach |

|---|---|---|---|---|

| GBP PRO S 1260 | 1250mm | 60t | 1050mm | 300mm |

| GBP PRO S 2065 | 2070mm | 60t | 1670mm | 300mm |

| GBP PRO S 20100 | 2070mm | 100t | 1670mm | 400mm |

| GBP PRO S 25100 | 2505mm | 100t | 2100mm | 400mm |

| GBP PRO S 25135 | 2505mm | 135t | 2100mm | 400mm |

| GBP PRO S 25175 | 2505mm | 175t | 2100mm | 400mm |

| GBP PRO S 30100 | 3150mm | 100t | 2600mm | 400mm |

| GBP PRO S 30135 | 3150mm | 135t | 2600mm | 400mm |

| GBP PRO S 30175 | 3150mm | 175t | 2600mm | 400mm |

| GBP PRO S 30220 | 3150mm | 220t | 2600mm | 400mm |

| GBP PRO S 30320 | 3100mm | 320t | 2600mm | 400mm |

| GBP PRO S 37175 | 3700mm | 175t | 3100mm | 400mm |

| GBP PRO S 37220 | 3700mm | 220t | 3100mm | 400mm |

| GBP PRO S 40175 | 4100mm | 175t | 3600mm | 400mm |

| GBP PRO S 40220 | 4100mm | 220t | 3600mm | 400mm |

| GBP PRO S 40320 | 4100mm | 320t | 3600mm | 400mm |

| GBP PRO S 40400 | 4100mm | 400t | 3600mm | 400mm |

| GBP PRO S 60220 | 6100mm | 220t | 5600mm | 400mm |

| GBP PRO S 60320 | 6100mm | 320t | 5600mm | 400mm |

| GBP PRO S 60400 | 6100mm | 400t | 5600mm | 400mm |