CNC-controlled, hydraulic press brake GBP BASIC S

Three driven axes, 2D standard control Cybelec CybTouch 12, motorised crowning and manual upper tool quick clamping

Product Details

As the name suggests, the GBP BASIC S is our basic version. The press brakes of this line are equipped with three controlled axes (Y1, Y2, and R) and the automatically controlled, motorised table crowning in the standard scope of delivery. The height adjustment of the backgauge fingers (R-axis) is manual, but can also be motorised as an option. The Cybelec CybTouch 12 2D standard control is very user-friendly and has a wide range of functions that leaves almost nothing to be desired. Alternatively, you can choose the Delem DA-58T control. With the GBP BASIC S series we cover working widths from 1250mm to 6100mm and press capacities from 60t to 400t.

- Graphical 2D control Cybelec CybTouch 12 with touch interface

- two linear encoders (OPKON) on the upper beam for checking the desired position with 0.01mm resolution

- CNC-controlled backgauge with two backgauge fingers

- X-axis double linear guided and driven by AC motor via recirculating ball screws

- Manual height adjustment of the backgauge fingers (R axis) via spindles and handwheels

- Backgauge finger manually adjustable laterally on linear guide

- Fiessler AKAS II safety laser with Fiessler FMSC press safety control system

- CNC-controlled, motorized crowning device to compensate for deflection

- Control panel on the right side of the machine on swivel arm

- Solid and low-maintenance quadruple guide of the press beam

- manual upper tool quick clamping, Promecam/Amada system, lateral removal

- Top tool (Promecam/Amada), height 104.65mm, split (box bending)

- Multi-V die (Promecam/Amada), height 60mm, V-opening widths 16/22/35/50mm, split (box bending)

- mobile double foot pedal with safety step and emergency stop impact switch

- two front support arms quickly adjustable laterally on linear guides

- Control-regulated oil volume distribution between the cylinders

- Monitoring of the relative position between the cylinders during bending

- synchronized cylinders with high performance hydraulic components from HAWE (formerly Hoerbiger)

- electrical components from Schneider and Mitsubishi

- generously dimensioned cylinders manufactured from one block for maximum accuracy and service life

- large hydraulic tank to maintain the correct oil temperature

- Hydraulics protected by pressure relief valve

- Drive motors protected by appropriate circuit breakers

- Operating instructions with CE declaration of conformity and spare parts documentation

- Complete oil filling with brand hydraulic oil from Eni

- 2D CNC controls Delem DA-58T or CybTouch 15

- 2-Achsen Hinteranschlag X, R für die gesteuerte, motorische Höhenverstellung der Anschlagfinger

- Additional backgauge fingers or support brackets

- Second foot pedal for two-man operation

- Manual or fully automatic central lubrication

- Custom painting

- Special overhangs, installation heights and much more on request ...

Bending length and press force are essential factors when it comes to choosing the right press brake. If the required press force increases, the bending length also increases proportionally. The GBP BASIC S press brake is available with a bending length of 1,250 mm and a pressing force of 60 tonnes. The largest version has a bending length of 6,100 mm and a pressing force of 600 tonnes. Other sizes are available on request.

Impressions

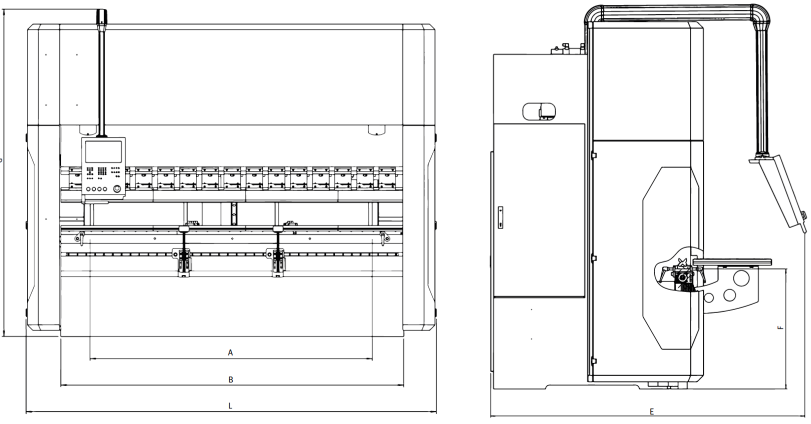

Construction

| Machine type | Working width | Pressing force | Stand passageway | Outreach |

|---|---|---|---|---|

| GBP BASIC S 1260 | 1250mm | 60t | 1050mm | 300mm |

| GBP BASIC S 2065 | 2070mm | 60t | 1670mm | 300mm |

| GBP BASIC S 20100 | 2505mm | 100t | 1670mm | 400mm |

| GBP BASIC S 25100 | 2505mm | 100t | 2100mm | 400mm |

| GBP BASIC S 25135 | 2505mm | 135t | 2100mm | 400mm |

| GBP BASIC S 25175 | 2505mm | 175t | 2100mm | 400mm |

| GBP BASIC S 30100 | 3150mm | 100t | 2600mm | 400mm |

| GBP BASIC S 30135 | 3150mm | 135t | 2600mm | 400mm |

| GBP BASIC S 30175 | 3150mm | 175t | 2600mm | 400mm |

| GBP BASIC S 30220 | 3150mm | 220t | 2600mm | 400mm |

| GBP BASIC S 30320 | 3100mm | 320t | 2600mm | 400mm |

| GBP BASIC S 37175 | 3700mm | 175t | 3100mm | 400mm |

| GBP BASIC S 37220 | 3700mm | 220t | 3100mm | 400mm |

| GBP BASIC S 40175 | 4100mm | 175t | 3600mm | 400mm |

| GBP BASIC S 40220 | 4100mm | 220t | 3600mm | 400mm |

| GBP BASIC S 40320 | 4100mm | 320t | 3600mm | 400mm |

| GBP BASIC S 40400 | 4100mm | 400t | 3600mm | 400mm |

| GBP BASIC S 60220 | 6100mm | 220t | 5600mm | 400mm |

| GBP BASIC S 60320 | 6100mm | 320t | 5600mm | 400mm |

| GBP BASIC S 60400 | 6100mm | 400t | 5600mm | 400mm |